New standards for energy efficiency, light intensity distribution and aesthetics

At a time when sustainability and energy efficiency are becoming increasingly important, intelligent coating systems are more in demand than ever. FreiLacke, the innovative system coating manufacturer from Bräunlingen in the Black Forest, has developed a solution with its reflection-optimised powder coatings that not only impresses in terms of functionality, but also opens up new avenues in design.

What are reflection-optimised powder coatings?

Reflection-optimised powder coatings have been specially developed to direct, reflect or scatter light in a targeted manner, depending on the application and requirements.

Typical areas of application:

These innovative coatings have a wide range of possible applications:

Lighting industry

- For reflectors, housings and light guides where high light output is desired.

building services

- Reduction of heat input through selective reflection – e.g. in facades, ceiling panels or slats.

Interior design & furniture construction

- For light control in room concepts with indirect lighting.

Technological basis

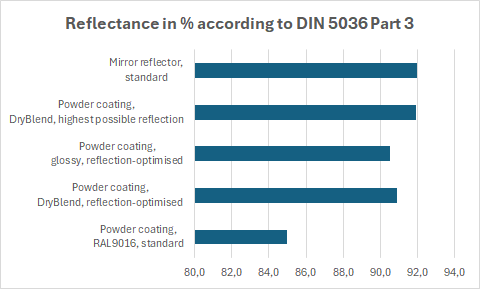

FreiLacke uses special raw materials in the development of reflection-optimised powder coatings, which are specifically tailored to the degree of reflection, surface topography and scattering behaviour. The formulations can produce both high diffuse reflection (ideal for even light distribution) and targeted mirror reflection (for direct light guidance).

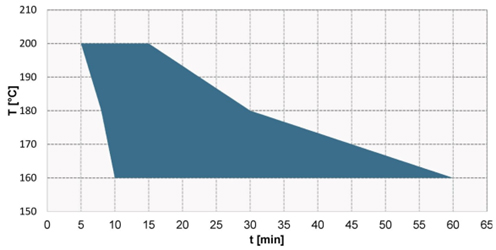

In a fundamental development, the development department at FreiLacke has succeeded in adapting the existing system to a low-temperature system with baking conditions of 10 minutes at 160°C.

In addition to high reflective properties and reduced baking temperatures, end customers have further requirements for powder coatings:

- Yellowing-resistant binders – good overbaking stability when baking the powder coating for 30 minutes at 200 °C, colour deviation dE <1

- Gloss level of 25 GE at an angle of 60°

- very good progress

- uniform appearance

- Very good application behaviour due to geometrically difficult painting objects, especially in corners

Overview of advantages for users and end customers

- Increased energy efficiency through reduction of burn-in conditions

- Sustainability: Solvent-free and VOC-free

- High functionality: Permanently weather and UV resistant

Practical example: Energy-efficient lighting systems

A leading manufacturer of lighting solutions has been using FreiLacke’s reflection-optimised powder coating for many years for the interior coating of its reflector housings.

In a joint project, the baking behaviour of the powder coating was further optimised and can now be cross-linked in 10 minutes at an object temperature of 160°C – a clear plus for energy efficiency and innovation.

"We have been using FreiLacke's reflective white for many years and are very satisfied with the processing, appearance and reflectivity of the powder coating. FreiLacke has provided us with significant support in reducing the baking conditions to a 10 min/160°C system, thereby increasing the efficiency of our production."

Nebojsa Andjelkovic / Zumtobel Group

Conclusion

With reflection-optimised powder coatings, FreiLacke offers a forward-looking solution for customers who not only think functionally, but also want to harmonise design and ecological aspects. Combined with proven system coating expertise and customer-oriented development, FreiLacke is a strong partner for sophisticated surface solutions.