Industrial coatings

Increase productivity with UV coating systems

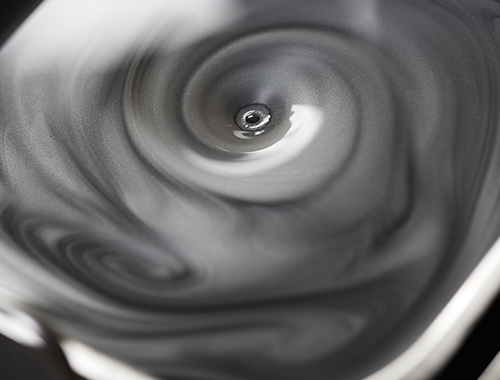

Coatings protect surfaces, provide them with new functions and refine them with special colours and haptic elements. UV coatings with environmentally friendly properties are becoming increasingly popular: Since nearly all of their components react with each other during the UV curing process, hardly any VOC emissions are produced when they are processed. That makes them a particularly interesting alternative to solvent-based coating systems, which are the subject of growing regulatory scrutiny.

UV coating systems from FreiLacke are curing particularly quickly and offer outstanding mechanical properties

UV coatings are applied using a rolling or spraying process. They are dried using sources of radiation that emit ultraviolet light and do not require a lot of heat. The photo initiators contained in the coating absorb the energy from the light and disaggregate, which triggers a chain reaction – following a short, high-energy radiation, the UV coating systems are cured. The advantage: The coated substrates can immediately be processed further, packaged or stacked. That results in an increase in productivity in the manufacturing sector.

FREODUR UV primer ES1919 - UV primer for metal coating

This UV-curing, white-pigmented primer is characterised by excellent metal adhesion, especially on aluminium panels. It can be coated by roller application but also by hot spraying and forms the ideal substrate for subsequent coatings such as UV digital printing ink and UV clear coat.

All benefits at a glance:

- Excellent metal adhesion

- Roll application or hot spraying process possible

- Optimum substrate

All benefits at a glance:

- Ideal for printed surfaces

- Scratch and abrasion resistant

- Very good chemical resistance

FREODUR UV clearcoat ES1903 - scratch-resistant and high-gloss for interior applications

This high-gloss UV clearcoat shows its strengths in the area of overcoating digitally printed surfaces such as coil-coated sandwich panels.

It has excellent scratch and abrasion resistance and very good chemical resistance. It is mainly applied by spraying, but industrial roller application can also be used.

FREODUR UV Clearcoat ES1970 – glossy and flexible

his flexible, glossy UV Clearcoat system is available to you for coating digital-printed aluminium panels. These coated panels can be bent without cracking using specially adapted reshaping techniques. This coating is very resistant to chemicals so it is able to comply with the DIN 68861-1 standard for furniture. Despite the high flexibility of this coating, it provides excellent resistance to abrasion. Another advantage is good resistance to humidity, including at bending points. Modification with light stabilisers means that this 1-component coating system can also be used outdoors. On digitally printed surfaces, even after 5000 hours of short-term weathering in the Weatherometer, it shows very good gloss retention and colour stability. This is due primarily to the choice of appropriate light-resistant printing inks.

All benefits at a glance:

- Great flexibility

- Reshaping is possible

- Good resistance to chemicals

- Good light and weather resistance after an optional modification

FREODUR UV Clearcoat ES1987 – the deep-matt spray coating

This matt UV Clearcoat product is available for industrial roller applications using a gloss roller. It achieves excellent flow properties in layer thicknesses of 5 to 8 microns and is characterised by good adhesion on coil-coated substrates as well as on digitally printed surfaces. Gloss levels of < 10 gloss units can be achieved at an angle of 60°.

All benefits at a glance:

- Good flow properties with low application volumes

- Good adhesion to printed surfaces

- Applied with a gloss roller

All benefits at a glance:

- Certified non-slip effect for floor area R11 B

- Easy-clean properties

- Matt surface finish

- Good abrasion resistance

FREODUR UV Clearcoat ES1927 – the non-slip coating for floors

ES1927 is a UV-curable coating with an R11 B non-slip effect. It is used to coat a wide range of different substrates such as digitally printed adhesive films and primed metal substrates on floors. Tested on an inclined plane in accordance with DIN 51130 and in barefoot areas in accordance with DIN EN 16165. (illustration showing both certificates). In addition to the non-slip effect, further special features are its matt surface finish, good resistance to abrasion and ease of cleaning. The coating is applied using an industrial roll coater so that the required application volume to achieve the specified slip resistance class is guaranteed.

FREODUR UV Clearcoat ES1901 – for decorative exterior areas

Thanks to its binding agent composition and the use of special light stabilisers, Dual-Cure UV Clearcoat is highly resistant to light and weathering. It has excellent gloss retention and a low tendency to yellowing in outdoor weathering conditions (Central Europe) and in the Weatherometer short-term test which lasts for up to 5000 hours. There is the option of using a Dual-Cure curing agent to improve adhesion on critical, aged surfaces. This UV coating system is suitable for outdoor use to protect decoratively printed elements – provided that the printing inks have good light resistance. Through intense cooperation with printing equipment and ink manufacturers, optimum property profiles can be obtained. With uniform layer thicknesses of 30 to 40 microns, high-gloss surface finishes are achieved through industrial roller application.

All benefits at a glance:

- Good light and weather resistance

- Great flexibility

- Good adhesion to digital printing inks with Dual-Cure curing